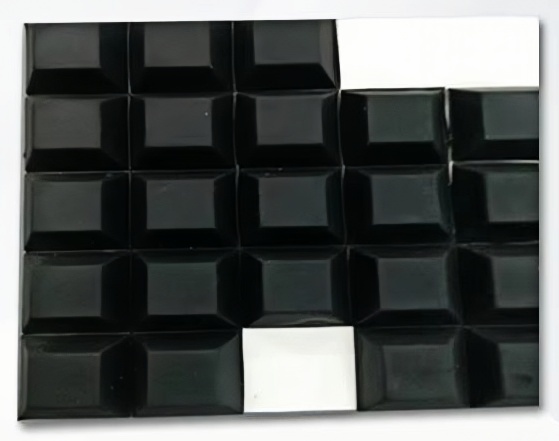

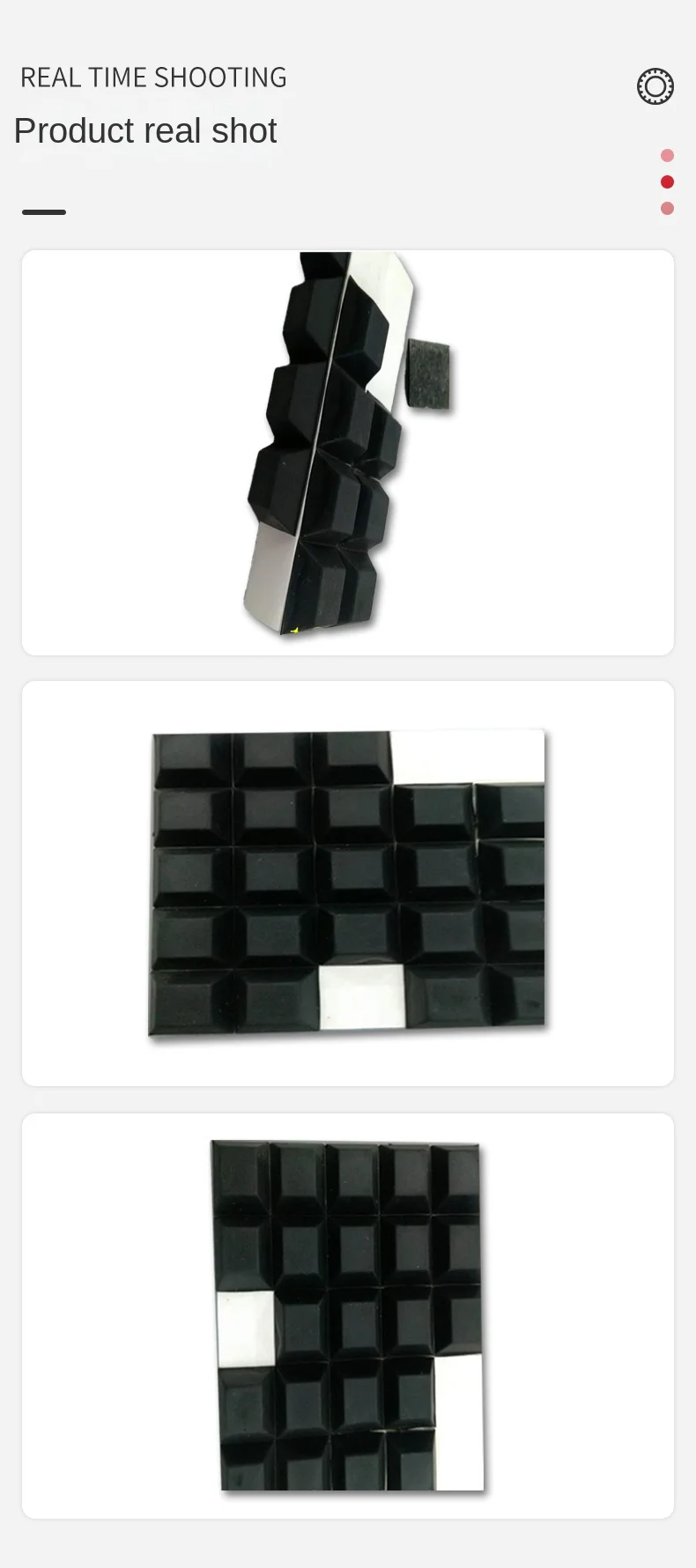

Adhesive Rubber Feet | NBR Rubber Pads for Industrial Use | Anti-Vibration and Non-Slip Solutions

Introduction:

Key Features:

- Adhesive Backing: Our rubber feet have a strong adhesive backing that allows for easy installation on various surfaces.

- Anti-Vibration: Our NBR rubber pads provide excellent anti-vibration properties, reducing noise and preventing damage to equipment and machinery.

- Non-Slip: Our pads offer excellent non-slip properties, preventing movement and ensuring stability in industrial settings.

- Durability: Our rubber feet are made from high-quality materials that ensure excellent durability and longevity, even in harsh industrial environments.

- Chemical Resistance: Our NBR rubber pads offer excellent resistance to chemicals, including oils, fuels, and cleaning agents.

Benefits:

- Reduced Noise: Our adhesive rubber feet can help reduce noise and vibration in industrial settings, creating a safer and more comfortable work environment.

- Prevented Movement: Our non-slip pads can help prevent movement and slipping of equipment and machinery, reducing the risk of accidents and injuries.

- Protected Surfaces: Our rubber feet can help protect surfaces from damage and scratches, reducing maintenance and repair costs.

- Customized Solutions: Our pads can be tailored to meet your specific needs, ensuring a perfect fit and optimal performance.

-

Easy to Install: Our adhesive rubber feet are easy to install and can be applied to various surfaces with minimal effort.

Specifications:

- Material: NBR (nitrile butadiene rubber)

- Size: Customizable (e.g., 1", 2", 3" diameter)

- Thickness: Customizable (e.g., 1/16", 1/8", 1/4")

- Adhesive: Strong acrylic adhesive

- Temperature Range: -20°C to 100°C (-4°F to 212°F)

|

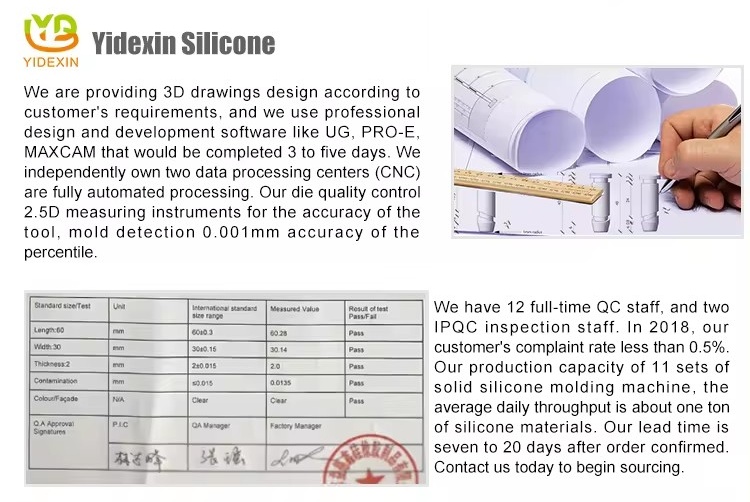

Available material |

Silicone: Common Silicone, High Tensile Silicone, Food Grade Silicone, Medical Grade Silicone, High Clear Silicone, etc.

Other special material requirements, please feel free to contact us to share your order.

|

|

Hardness |

10~80Shore A |

|

Color |

PMS color |

|

Size/Specifications |

As per drawing dimensions |

|

Process |

Compression or injection |

|

Application |

For Automotive, Motorcycle,Machinery, Industrial |

|

Performance |

Aging resistance,ozone resistance, oil resistance,tears and abrasions resistance |

|

Certification |

IATF 16949 / ISO 9001/ ISO 45001/ ISO 14001 /REACH/ROHS/MSDS/LFGB |

|

Surface Treatment |

Matte, Common polishing, Mirror polishing, Texture, Laser Engraving, Power Coating (Painting), Printing, Segmented colors, Mixed colors, etc. |

|

Mold Material |

No. 50 steel, No. 45 steel, P20, 8407, H13, 718H, etc. |

|

Mold Precision |

If no special request, apply to ISO3302:2014 standards, class 2. |

|

OEM / ODM |

Available |

|

Samples |

We would provide free available samples |

|

Packing Details |

PE plastic bags then to the carton / as per your request |

|

Price Tip |

The price shown above is just for reference, final actual price depends on your design, material request, surface treatment, order |

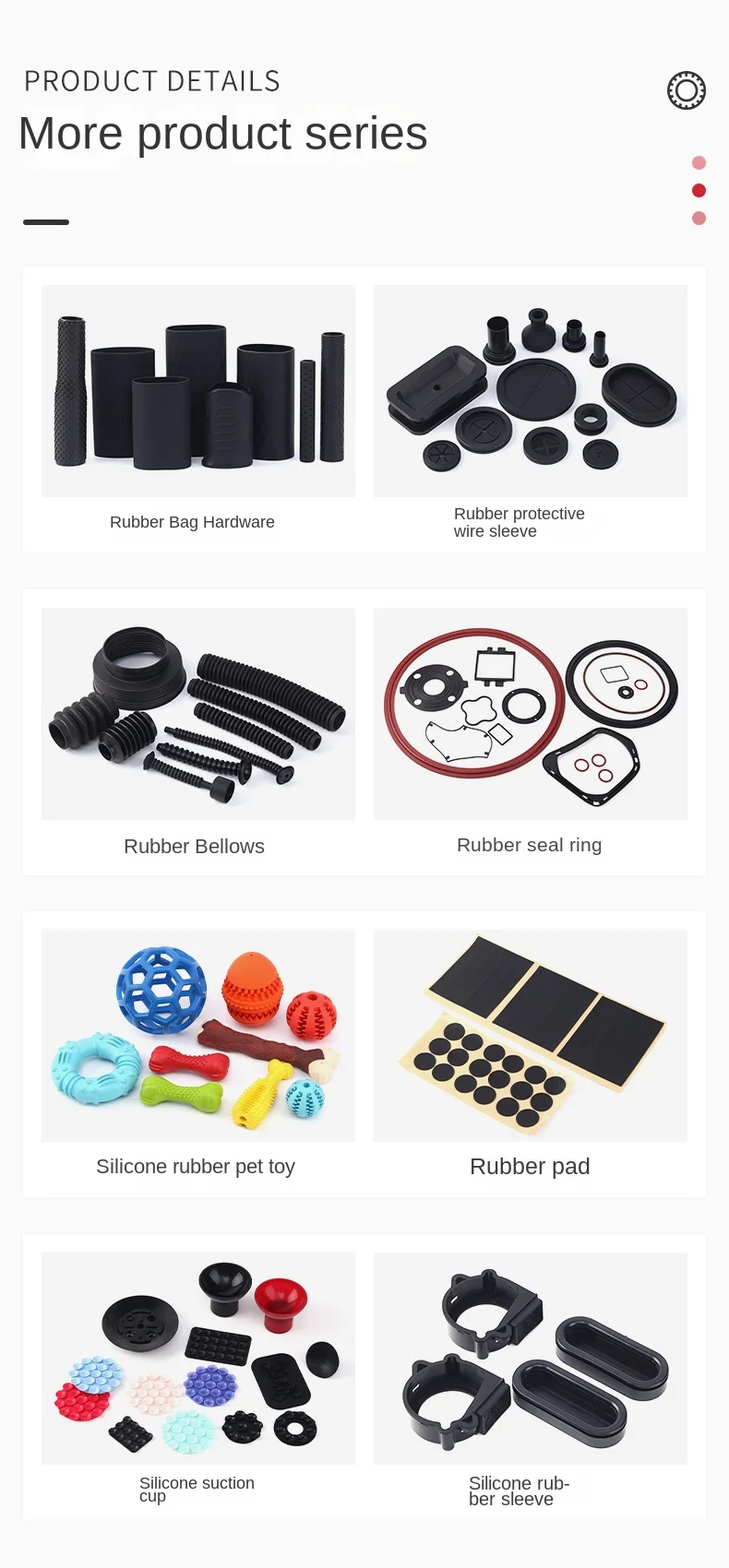

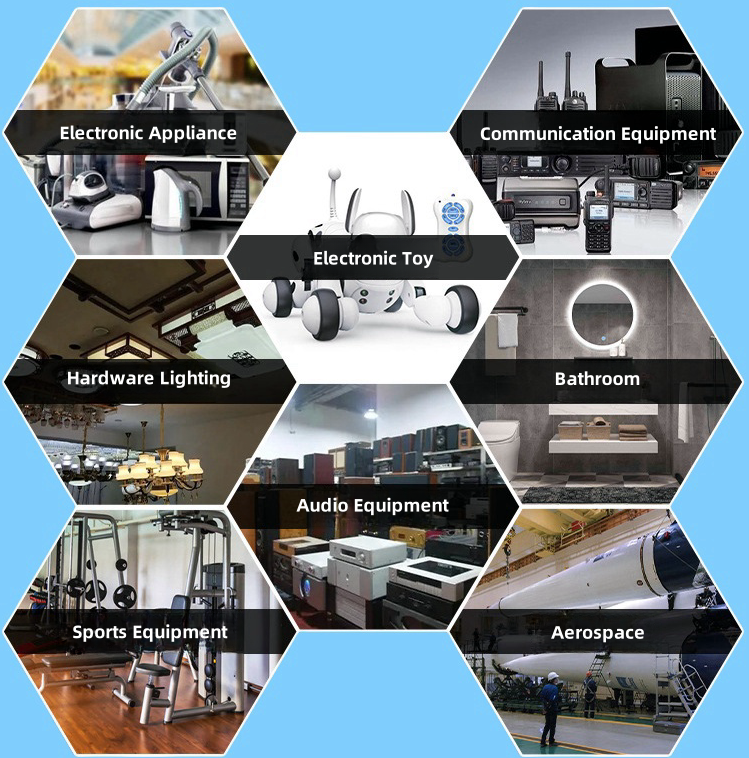

Applications:

- Industrial Machinery: Reducing noise and vibration in industrial machinery and equipment.

- Furniture: Preventing movement and slipping of furniture and equipment in industrial and commercial settings.

- Electrical Equipment: Protecting electrical equipment from damage and scratches in industrial and commercial settings.

- Automotive: Reducing noise and vibration in automotive applications, including vehicles and equipment.

- Aerospace: Reducing noise and vibration in aerospace applications, including aircraft and equipment.

English

English Deutsch

Deutsch español

español

86-592-5659128 (to8016)

86-592-5659128 (to8016)

+86-13606037597

+86-13606037597