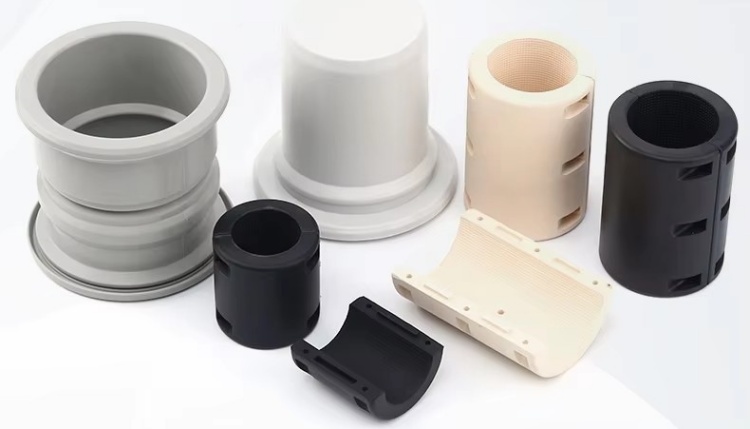

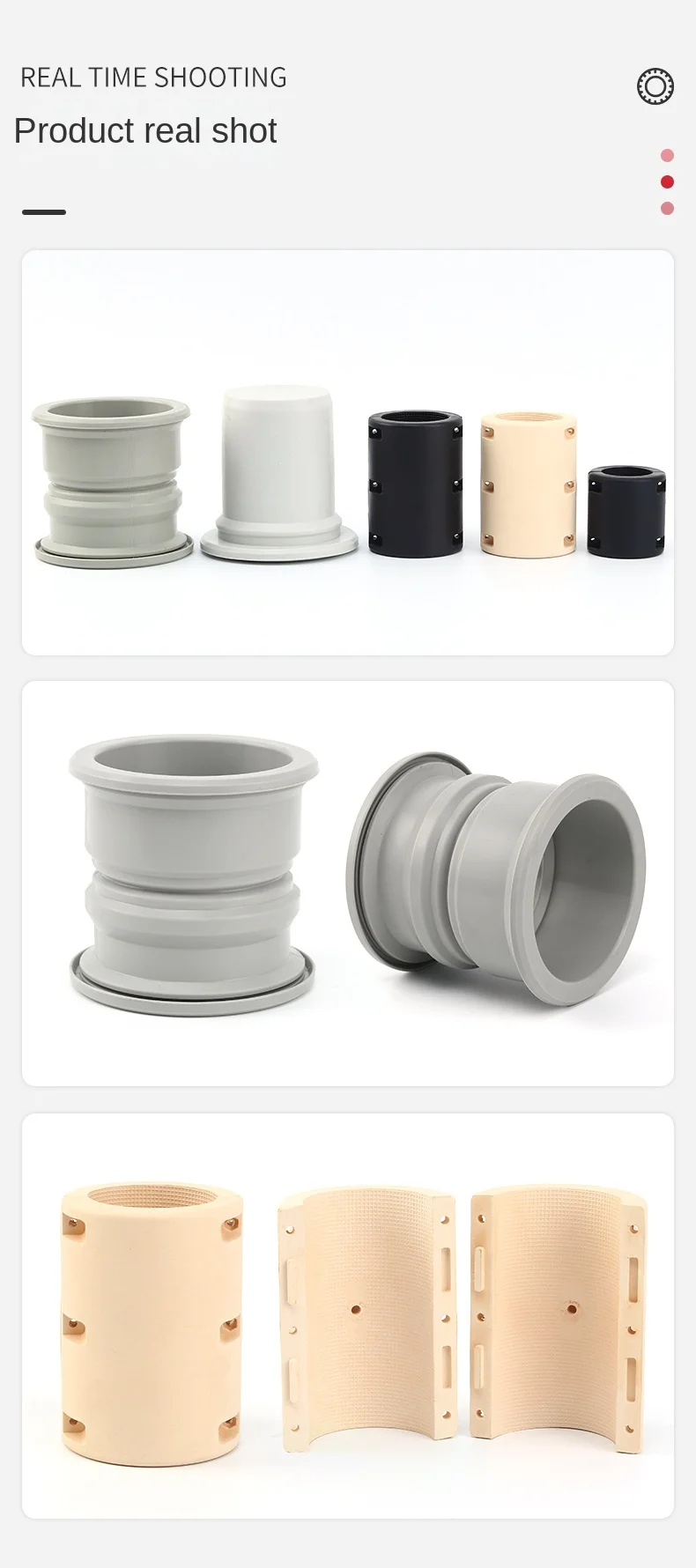

Custom High-Quality Silicone Rubber Sleeve Bushing | Precision Engineered Silicone Sleeves

Introduction:

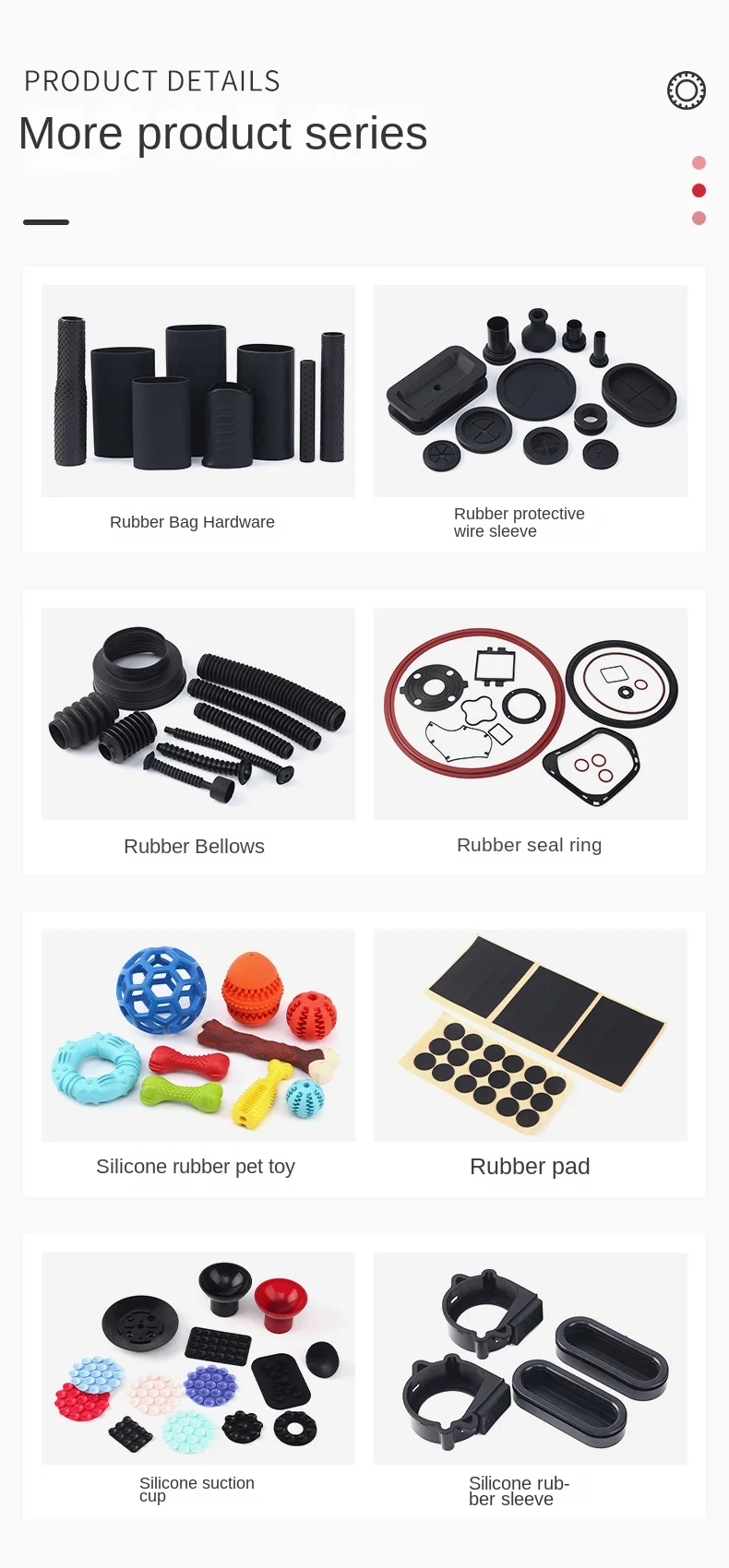

Our custom high-quality silicone rubber sleeve bushing is designed to provide a precise and reliable solution for various industrial applications, including electrical insulation, vibration dampening, and mechanical protection. Made from high-quality silicone materials, these sleeves offer excellent durability, flexibility, and resistance to extreme temperatures, chemicals, and abrasion. Whether you need to protect cables, wires, or other components, our custom silicone rubber sleeve bushing is the perfect choice.

Key Features:

- Customizable Silicone Sleeves: Our sleeves can be tailored to meet your specific requirements, including size, shape, color, and durometer (hardness).

- High-Quality Silicone Materials: Our sleeves are made from premium silicone materials that ensure excellent performance and longevity.

- Precision Engineered: Our sleeves are precision engineered to provide a snug fit and optimal performance.

- Electrical Insulation: Our sleeves can be used to provide electrical insulation and protection for cables, wires, and other components.

- Vibration Dampening: Our sleeves can also be used to reduce vibration and noise in mechanical systems.

Benefits:

- Improved Performance: Our custom silicone rubber sleeve bushing provides excellent electrical insulation, vibration dampening, and mechanical protection.

- Enhanced Durability: Our sleeves are made from high-quality silicone materials that ensure long-lasting performance and resistance to extreme temperatures and chemicals.

- Customized Solutions: Our sleeves can be tailored to meet your specific needs, ensuring a perfect fit and optimal performance.

- Easy Installation: Our sleeves are easy to install and can be slipped over cables, wires, or other components with minimal effort.

-

Cost-Effective: Our custom silicone rubber sleeve bushing is a cost-effective solution for protecting and insulating components.

Specifications:

- Material: High-quality silicone

- Durometer: Customizable (e.g., 30-90 Shore A)

- Color: Customizable (e.g., black, white, red, etc.)

- Size: Customizable (e.g., diameter, length, etc.)

- Temperature Range: -50°C to 200°C (-58°F to 392°F)

|

Available material |

Silicone: Common Silicone, High Tensile Silicone, Food Grade Silicone, Medical Grade Silicone, High Clear Silicone, etc.

Other special material requirements, please feel free to contact us to share your order.

|

|

Hardness |

10~80Shore A |

|

Color |

PMS color |

|

Size/Specifications |

As per drawing dimensions |

|

Process |

Compression or injection |

|

Application |

For Automotive, Motorcycle,Machinery, Industrial |

|

Performance |

Aging resistance,ozone resistance, oil resistance,tears and abrasions resistance |

|

Certification |

IATF 16949 / ISO 9001/ ISO 45001/ ISO 14001 /REACH/ROHS/MSDS/LFGB |

|

Surface Treatment |

Matte, Common polishing, Mirror polishing, Texture, Laser Engraving, Power Coating (Painting), Printing, Segmented colors, Mixed colors, etc. |

|

Mold Material |

No. 50 steel, No. 45 steel, P20, 8407, H13, 718H, etc. |

|

Mold Precision |

If no special request, apply to ISO3302:2014 standards, class 2. |

|

OEM / ODM |

Available |

|

Samples |

We would provide free available samples |

|

Packing Details |

PE plastic bags then to the carton / as per your request |

|

Price Tip |

The price shown above is just for reference, final actual price depends on your design, material request, surface treatment, order |

Applications:

- Aerospace: Protecting and insulating cables, wires, and other components in aircraft, spacecraft, and missiles.

- Automotive: Protecting and insulating components in vehicles, including electrical systems, fuel systems, and brake systems.

- Industrial Manufacturing: Protecting and insulating components in machinery, equipment, and pipelines.

- Electronics: Protecting and insulating electronic components, including PCBs, connectors, and switches.

- Renewable Energy: Protecting and insulating components in wind turbines, solar panels, and other renewable energy systems.

English

English Deutsch

Deutsch español

español

86-592-5659128 (to8016)

86-592-5659128 (to8016)

+86-13606037597

+86-13606037597