86-592-5659128 (to8016)

anna@xmydx.com86-592-5659128 (to8016)

anna@xmydx.com

2025-05-15 11:54:50

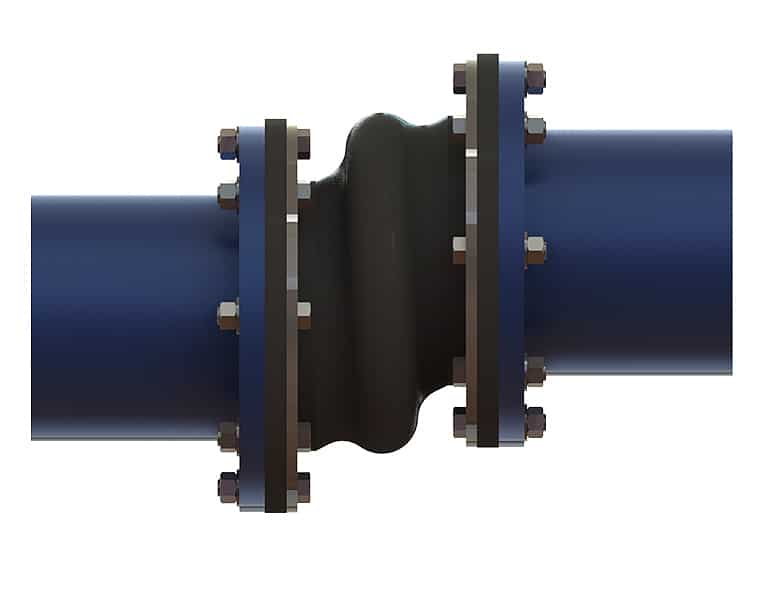

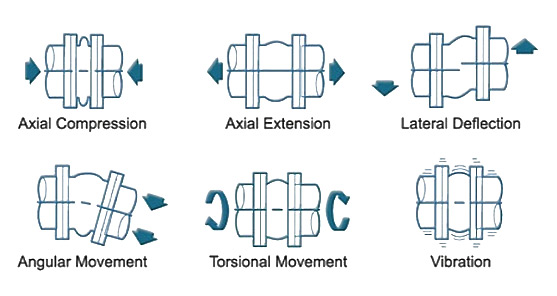

Rubber expansion joints are critical components in industrial, HVAC, plumbing, and infrastructure systems. They absorb vibrations, accommodate movement, and prevent stress damage in pipelines, ducts, and machinery. But how long can you expect them to last?

The average lifespan of a rubber expansion joint ranges from 5 to 15 years, depending on several factors. Below, we break down the key influences on durability and share actionable tips to maximize their service life.

Material Quality

Operating Conditions

Installation Quality

Maintenance Practices

Choose the Right Material

Ensure Proper Installation

Regular Inspections

Protect Against Environmental Stressors

Avoid Overloading

Q1: Can rubber expansion joints be repaired instead of replaced?

A: Minor cracks or leaks may be temporarily repaired with rubber patches or sealants. However, severe damage requires replacement to avoid system failure.

Q2: What’s the best rubber for high-temperature applications?

A: EPDM and Silicone rubber joints are ideal for high-heat environments (up to 200°C).

Q3: How does UV exposure affect rubber expansion joints?

A: UV radiation breaks down rubber molecules, causing surface cracking. EPDM is UV-resistant and suitable for outdoor use.

Q4: Are there industry standards for testing rubber expansion joints?

A: Yes, standards like ASTM D2000 (rubber material classification) and MIL-R-6130 (military specifications) ensure quality and durability.

The lifespan of rubber expansion joints depends on material selection, environmental conditions, installation quality, and maintenance. By choosing the right rubber type, adhering to installation standards, and performing routine checks, you can maximize their service life and avoid costly downtime.

If your system operates under extreme conditions, consider upgrading to high-performance materials like fluorocarbon rubber or reinforced composites. Always consult a professional for critical applications!

© 2016 XIAMEN YIDEXIN SILICONE RUBBER INDUSTRIAL CO.,LTD All Rights Reserved dyyseo.com

Online Contact

86-592-5659128 (to8016)

86-592-5659128 (to8016) anna@xmydx.com

anna@xmydx.com sallyliao1985

sallyliao1985 xmydx02

xmydx02 +86-13606037597

+86-13606037597top