Silicone vs Rubber: Understanding the Differences

Silicone vs Rubber: Understanding the Differences

Introduction

Both silicone and rubber are widely used materials in industries, healthcare, and everyday life, but they have distinct differences that are crucial for making informed choices. This article explores the characteristics and applications of silicone versus rubber, highlighting their pros and cons.

Characteristics Comparison

1. Composition

-

Silicone: A synthetic material composed of organic silicon compounds, typically involving silicon dioxide (SiO2) and organic groups. It is chemically stable, heat-resistant, and weather-resistant.

-

Rubber: Can be natural or synthetic; natural rubber comes from latex extracted from rubber trees, while synthetic rubber is derived from petroleum products. Rubber is known for its elasticity and wear resistance.

2. Temperature Resistance

-

Silicone: Can withstand extremely high temperatures (over 200°C) and remains flexible at low temperatures, making it suitable for various environments.

-

Rubber: While some rubber types offer good temperature resistance, most degrade in high-temperature scenarios, limiting their use in such conditions.

3. Antimicrobial Properties

-

Silicone: Naturally antimicrobial and resistant to bacterial growth, making it popular in medical and food industries.

-

Rubber: Tends to absorb moisture and bacteria, requiring regular cleaning and sterilization.

4. Elasticity and Durability

-

Silicone: Exhibits excellent elasticity and resilience, with a longer lifespan compared to rubber.

-

Rubber: Elasticity and durability vary by type; however, it tends to degrade over time with extended use.

5. Environmental Impact

-

Silicone: More environmentally friendly, recyclable, and biodegradable, reducing environmental impact.

-

Rubber: Synthetic rubber may contain harmful chemicals, posing a burden on the environment.

Applications

1. Food Industry

-

Silicone: Widely used in food-contact products like baking molds and food storage containers due to its non-toxic and easy-to-clean nature.

-

Rubber: Less common in direct food contact applications but may be used in non-contact components.

2. Medical Field

-

Silicone: Commonly used in medical devices, tubing, and implants due to its biocompatibility and stability.

-

Rubber: Used in some medical applications but requires strict sterilization and maintenance.

3. Industrial Use

-

Silicone: Excel in high-temperature and chemical environments, suitable for seals and protective components.

-

Rubber: Commonly used where elasticity and wear resistance are needed, such as tires and seals.

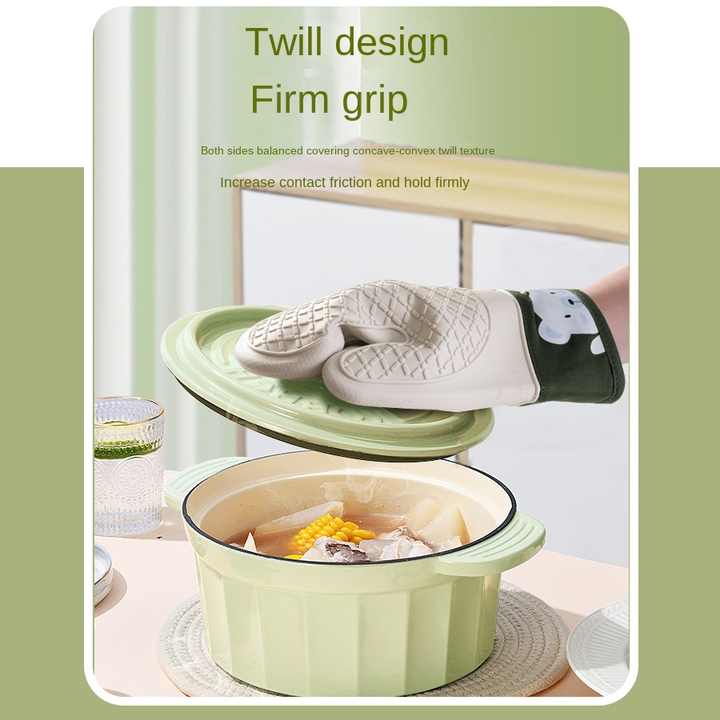

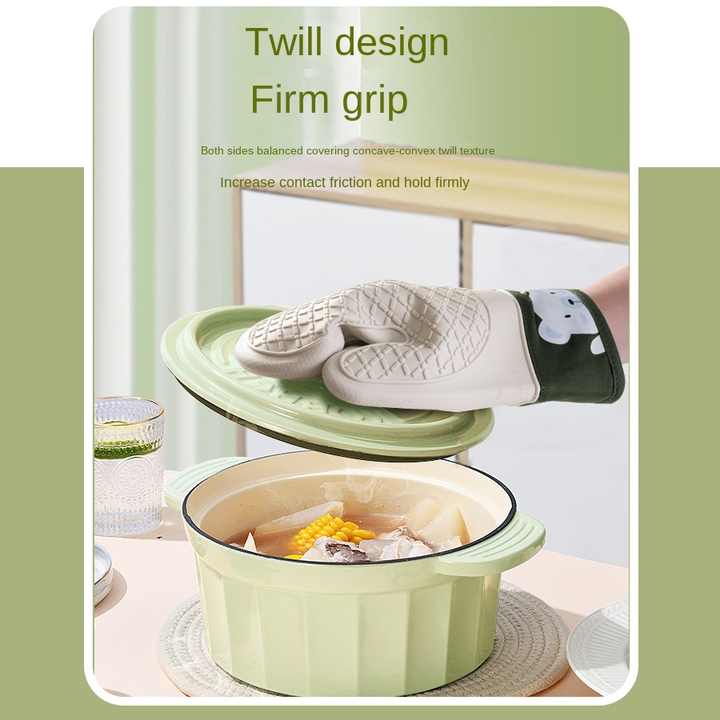

4. Everyday Life

-

Silicone: Used in kitchenware and personal care products, providing safety and convenience.

-

Rubber: Widely used in footwear, automotive parts, and more for its elasticity and durability.

Selection Recommendations

-

Choose Silicone: If you need heat resistance, antimicrobial properties, and ease of cleaning, especially in food and medical applications, silicone is the better choice.

-

Choose Rubber: If your application requires elasticity and wear resistance without exposure to high temperatures, rubber may be more suitable.

Conclusion

While silicone and rubber share some overlapping applications, their characteristics and advantages differ significantly. Understanding these differences can help you make informed decisions tailored to your specific project or product needs.

86-592-5659128 (to8016)

86-592-5659128 (to8016) anna@xmydx.com

anna@xmydx.com sallyliao1985

sallyliao1985 xmydx02

xmydx02 +86-13606037597

+86-13606037597