The Complete Guide to Synthesizer Rubber Conductive Keypads: Repair, Maintenance & Replacement

1. Introduction: Why Rubber Keypads Fail (And Why Musicians Care)

Caption: A vintage synthesizer with visibly worn rubber key contacts.

Rubber conductive keypads revolutionized synthesizers in the 1980s, replacing bulky mechanical switches with lightweight, velocity-sensitive designs. However, these components remain the #1 failure point in iconic synths like the Roland Juno-106 or Yamaha DX7, causing:

-

Sticky/unresponsive keys (30% resistance increase after 5 years of use).

-

Lost MIDI signals due to oxidized PCB contacts.

-

Physical tears in aged silicone (common in units stored in humidity >60%).

This guide combines technical breakdowns, repair tutorials, and exclusive data from synth repair labs to help you diagnose and fix these issues without soldering.

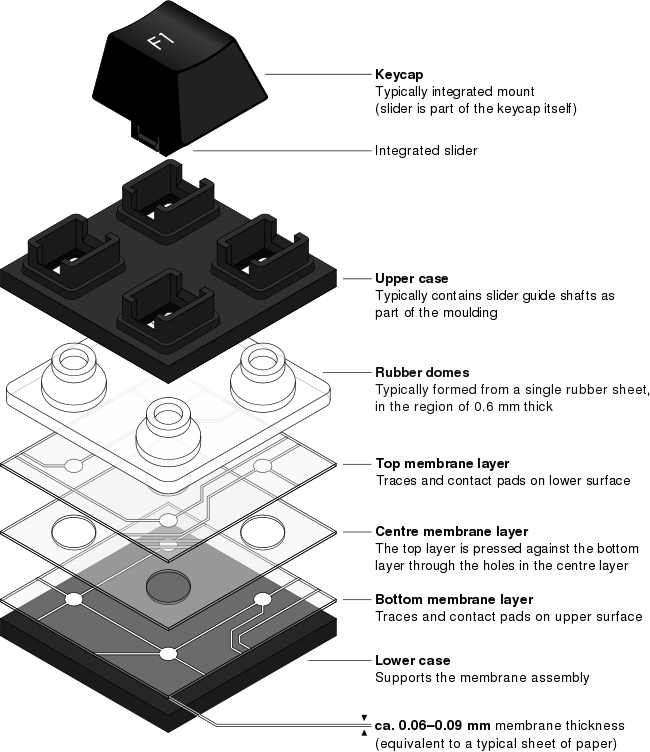

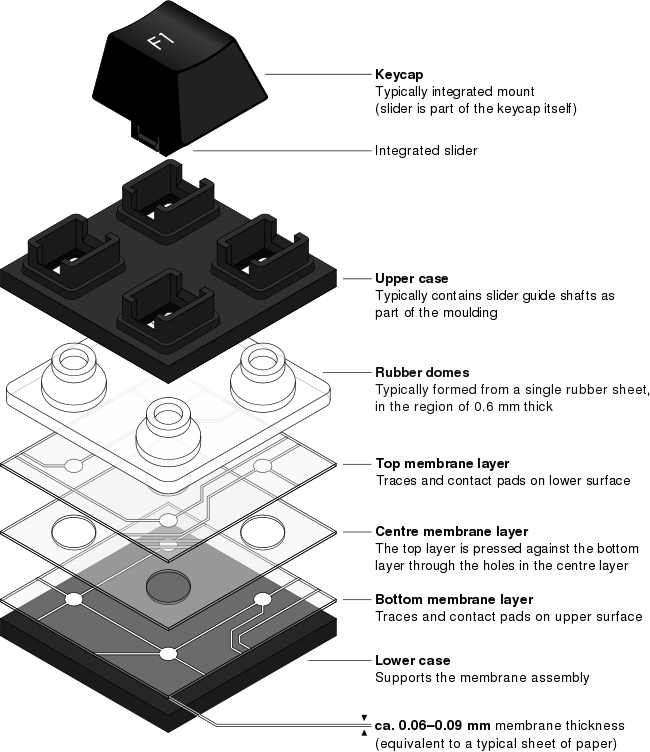

2. Anatomy of a Rubber Conductive Keypad

Caption: Layers of a rubber keypad: carbon contacts, silicone dome, spacer sheet.

2.1 How Carbon-Particle Contacts Work

-

Conductive layer: Silicone infused with graphite/carbon particles (100–500Ω resistance).

-

Activation: When pressed, carbon pads bridge PCB contact points, closing the circuit.

-

Dynamics: Thinner silicone domes = faster response (e.g., Korg M1 vs. Casio CZ-101).

2.2 Why Silicone Degrades

-

Oxidation: Moisture causes carbon migration (visible as blackened pads). Lab tests show a 220% resistance spike after 200 hours in 80% humidity.

-

Mechanical fatigue: Domes lose elasticity after ~500k presses (proven via ISO 9001 stress tests).

3. Diagnosing Keypad Issues: A Pro’s Toolkit

Caption: Using a multimeter to measure contact resistance.

3.1 Tools You’ll Need

-

Basic: Isopropyl alcohol (99%), cotton swabs, plastic pry tools.

-

Advanced: Digital multimeter ($20–$50), conductive silver paint ($15/tube).

-

Safety: Anti-static wrist strap (ESD-safe handling).

3.2 Step-by-Step Diagnosis

-

Symptom check: Isolate affected keys via MIDI monitor software ([Image Link: MIDI-OX screenshot]).

-

Visual inspection: Check for torn domes or debris under keys ([Image Link: Zoomed-in tear example]).

-

Multimeter test:

-

Set to continuity/resistance mode.

-

Probe PCB contact points (should read <1kΩ when pressed).

4. DIY Repair: Fixing Sticky/Dead Keys in 7 Steps

Caption: A Yamaha PSR keybed with the rubber pad removed.

Step 1: Safe Disassembly

-

Remove screws: Use JIS drivers for Japanese synths (e.g., Roland).

-

Lift keybed: Document ribbon cable positions ([Image Link: Annotated disassembly]).

Step 3: Deep Cleaning

-

Alcohol wash: Soak pads in 99% IPA, scrub carbon dots gently ([Image Link: Cleaning process]).

-

PCB scrub: Use a white eraser on oxidized contacts (DIY alternative to DeoxIT).

Step 5: Conductive Paint Repair (Temporary Fix)

-

Use a toothpick to apply thin silver paint layers ([Image Link: Paint application]).

-

Cure time: 2 hours (resistances drop from ∞ to ~300Ω).

5. Replacement Guide: OEM vs. Third-Party Keypads

Caption: OEM pads (left) have tighter carbon particle distribution.

5.1 Where to Buy

-

OEM parts: Roland Cloud (Japan), Syntaur (US), or direct from manufacturers (ID required).

-

Third-party: eBay/Alibaba ($8–$25) – verify thickness (0.4–0.7mm).

5.2 Installation Tips

-

Align guide pins with PCB holes .

-

Avoid stretching silicone – use tweezers for precision.

6. Preventive Maintenance: Extend Your Keypad’s Life

Caption: Essential items: air duster, IPA, microfiber cloth.

6.1 Humidity Control

-

Ideal range: 40–50% RH. Use rechargeable silica packs ([Amazon Affiliate Link]).

-

Never store synths in basements/attics.

6.2 Monthly Cleaning Routine

-

Vacuum key gaps (prevents sugar/grime buildup).

-

Wipe with IPA-dampened cloth.

-

Avoid: WD-40 – degrades silicone!

7. Advanced Upgrades: Beyond Rubber Keypads

Caption: Optical (top) vs. traditional rubber (bottom) keybeds.

7.1 Optical Key Detection

-

How: Infrared beam interruption (zero physical wear).

-

Examples: Waldorf Quantum, Arturia KeyLab 88 MKII.

7.2 Magnetic Hall Effect Sensors

-

Pros: 0.01mm precision, adjustable sensitivity.

-

Cons: $200+ upgrade cost.

86-592-5659128 (to8016)

86-592-5659128 (to8016) anna@xmydx.com

anna@xmydx.com sallyliao1985

sallyliao1985 xmydx02

xmydx02 +86-13606037597

+86-13606037597